The aftermath of the deadly Japanese earthquake and tsunami continues to leave the Asian country on alert. Earthquake aftershocks following the violent 8.7 magnitude shake, massive rationing of everyday goods, power supply and nuclear radiation concerns as well as the fact that many unfortunate people have lost lives has provided a reason for sombre time. However, some optimism reigns for when the sadness can be dealt with moving forward. Japanese auto companies (like many other industries and offices in the region) have positioned themselves along with their employees taking stock in the recent events, helping whenever possible.

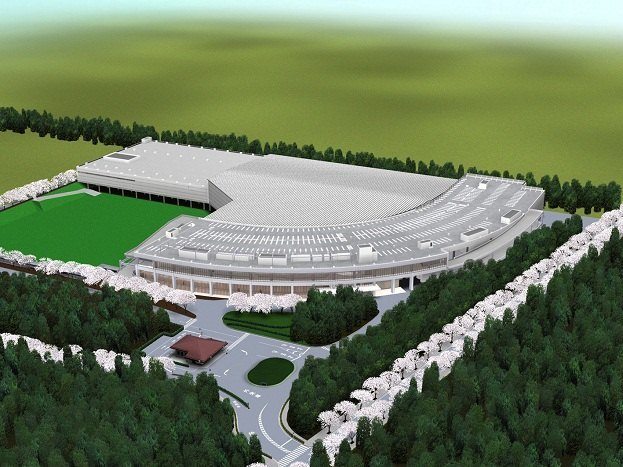

Honda, Nissan and Toyota provided immediate, official accounts to damage and injures but several waited until further evaluations of the aftermath before releasing statements. After company assessments over the weekend Mazda, Mitsubishi Motors, Subaru and Suzuki reported on the situation of their operations. Mazda, Mitsubishi Motors and Suzuki sent out word Monday that their factories and headquarters escaped damage. This was not an immediate surprise since most of these automakers’ infrastructure was in the southern part of Japan, away from the earthquake epicenter. Despite minor damage to equipment, Subaru as well as its parent Fiji Heavy Industries, survived with the seismic event without loss.

Cooperating with energy conservation efforts in Japan as well as to insure the safety of employees, all automakers have suspended production for the Monday and Tuesday. The temporary ceasing of automotive manufacturing operations is also performed following assessment of several facilities and suppliers reported damage.

While the industry is currently idled in Japan, most of the country’s automaker who did not suffer major damage intends to be restarted later this week. Subaru, Toyota and some Nissan facilities plan to resume production on March 16th while Mitsubishi Motors has production set to restart the next day. Planning initially to be restarted Wednesday the 16th, Mazda revised their production idle to the 20th of March. Mazda cited their shutdown extension as a move to assure their employee’s well-being.

While some plants are set to restart production on the 16th of March, Nissan and Honda plans regarding their harder hit operations will have some of the Japanese auto company starting later. Though the corporation reported six of their manufacturing plants suffering stress from the earthquake, Nissan’s Tochigi Plant (production facility for most notably the GT-R supercar) and the Iwaki Plant (builder of Nissan VQ series engines) sustained concerning damage in the natural disaster. Following the earthquake, fires were reported at both Nissan manufacturing plants that were promptly doused before spreading. With no major injuries or serious damage, Nissan will have the Tochigi Plant and Iwaki Plant complexes back in production by the March 18th.

Honda has been the only manufacturer to announce an on-site death of an employee. A 43-year old R&D associate in Tochigi was killed when a wall collapsed in the building’s cafeteria. While reporting one death, Honda injury toll in Tochigi is revised to 17 employees (dropping from an original account of 30). Suspending production until the next week, Honda’s intends to restart production of all plants for the 20th of March.

In their most recent press release, Honda also mentions the status of North American automobile production and supply. Saying the current situation has no immediate impact on the manufacturing plant in the United States and Canada. However, Honda is actively monitoring the supply line. Well 80% of their products are produced in North America, the Honda CR-Z, Fit as well as the Acura RL and TSX are imported directly from the recently closed Japanese facilities. Honda is also convinced they have enough Japanese-made vehicle components to sustain plants in the United States and Canada. Toyota and Nissan, who have manufacturing presence in the United States, were able to follow Honda’s suit by assuring North American stock of parts is sufficient for the short-term. However, Nissan is cautioning there will be delivery delays of the GT-R and 370Z. Fortunately for the company and North American customers, a ship of 600 Nissan Leaf electric vehicles that left a day ahead of the earthquake and tsunami is proceeding safely to the United States.

There are those who believe that an industry who propel people to prosperity. In reality, the converse is actually true. The Japanese people, despite their cultural of discipline and self-motivation, have been positioned in a time of need. Among those helping the cause for aid and assistance is Japan’s home-based auto companies. Honda, Toyota, Mazda and Nissan have donated a collective amount of 660 million yen (roughly the equivalent of $8.23 million US dollars) to aid efforts. Mitsubishi Corporation itself has provided 400 million yen (almost 5 million US dollars) in immediate aid to the relief preparations. Honda North America has also pledged to match Red Cross donations of the 29,000 employees without limit. Beyond monetary assistance, Honda is also donating 1,000 portable gas generators and 5,000 gas canisters. Nissan’s non-monetary work included the donation of vehicles and fork lifts as well as food and blankets. Most notably on the 11th of March, Nissan Global Headquarters in Yokohama City served as temporary shelter to 150 people affected by the natural disaster. In the building, food and warmth were provided in a show of corporate/community spirit.

The human toll is compiled in number, but the tragic reality is many of us can never be accurately measured since there is no true measure of a value of an individual life. As charity and human kindness is extended to the Japanese public in this dark time, we like forward to a brighter future as a global community whether dealing with a large corporate or a single person. One person expressing this hope is Toyota president Akio Toyoda who issued a personal statement first expressing “I offer my prayers to all those who lost their lives in the March 11 Tohoku Earthquake and its ensuing aftermath, as well as my sympathy to the survivors and their families.” Acknowledging the relief effort as the first priority, Toyoda ended saying “Determined to provide hope for not only those suffering and forced to undergo extreme hardships, but also for the region overall, we will do our utmost toward the realization of recovery.”

Information source: American Suzuki Motor Corporation, Honda Motor Company, Mazda Motor Corporation Mitsubishi Motors, Nissan Motor Company, Subaru, Toyota Motor Corporation

Photo source: Mazda Motor Corporation